Category:

How Long Do Diesel Engines Last? Longer Than Cars?

Between diesel and gasoline engines, diesels are the clear winner in performance and longevity. A diesel engine’s robust design, gear-driven components, and operating efficiency trump smaller, harder-working gasoline engines.

Use the guide below to explore why diesel engines last longer than cars and how you can prolong the life of your diesel engine for thousands more miles to come.

How Many Miles Can Diesel Engines Last?

Diesel engines can last an average of 500,000 to 1 million miles, provided they’re well-maintained and cared for. Compare this to the average lifespan of a gasoline engine, which typically ranges from 200,000 to 250,000 miles.

Although diesel engines tend to last twice as long as — or longer than — the average gasoline powerplant, the odometer reading doesn’t tell the whole story. Most diesel-powered vehicles spend their lives on the highway, racking up thousands of annual miles as they travel to and from job sites.

While the average passenger vehicle covers 15,000 miles a year, diesel-powered semi-trucks and heavy-duty haulers average anywhere from 50,000 to 100,000 miles annually.

With up to 100,000 miles or more put on the odometer every year, diesel engines can quickly reach the 500,000-mile mark. However, these engines are often repaired or rebuilt multiple times along the way, especially under extreme operating conditions.

It also costs much more to replace a diesel engine (let alone the truck it’s housed in) than your typical gas-powered engine.

Why Do Diesel Engines Last Longer Than Gasoline Engines?

One important aspect of the diesel vs. gas debate is the distinction between personal and commercial applications.

Diesel engines are typically used for heavy-duty commercial applications, such as mining and construction, while gasoline engines power most personal vehicles on the road. However, diesel engines tend to outlive gasoline engines for the following reasons.

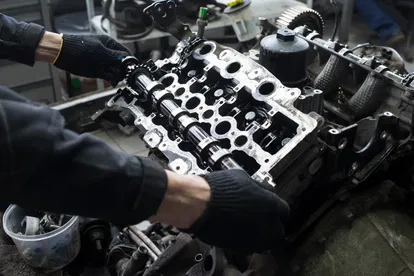

More Robust Engine Design

A diesel engine’s cast iron block and cylinder heads are well-suited to withstand the higher compression required for diesel fuel combustion.

Cylinder sleeves offer greater serviceability, taking the brunt of any damaging forces and protecting the block from significant damage. A longer piston stroke increases the distance between the piston head and the pressure and heat generated during combustion.

Most major diesel engine components are also larger and more robust than their gas engine equivalents. Crankshafts, camshafts, and main engine bolts must adhere to a higher specification based on normal diesel operating conditions. A diesel engine’s cooling system also expands, incorporating a larger radiator, oil cooler, intercooler, and secondary thermostat.

The amount of oil that diesel and gasoline engines require also reflects the design differences. Diesel engines have a greater capacity and clearance for lubrication, meaning you’ll need more than a few quarts to top them off after every oil change.

However, oil change intervals are generally fewer and farther between when compared to gasoline engines.

Gear-Driven Powerplant

Unlike timing chain or belt-driven gasoline engines, diesel engines are gear-driven and don’t lose timing like chains or belts are prone to do. It takes significant force or extreme operating conditions to damage the gears, but they can be more easily repaired without full replacement.

Diesel Fuel Acts Like a Lubricant

While gasoline and diesel are both derived from crude oil, gasoline acts more like a solvent because it’s more refined. Diesel resembles a lubricant that helps reduce friction and prevent wear within the engine. It’s also less volatile than gasoline.

Cooler Operating Conditions

Diesels generate most of their power and torque at lower RPMs, which allows for leaner air-fuel ratios and lower auto-ignition temperatures. As a heavy-duty rotating assembly, a diesel engine performs better at lower speeds than a gasoline engine, producing peak power and torque at higher RPMs.

What Are the Pros and Cons of Diesel Engines?

A diesel engine powers the heart of numerous industrial applications, from farms to fleets. While it can bear the brunt of extreme working conditions better than gasoline, it’s not always the best choice for every application.

Read on to discover the advantages and disadvantages of diesel engines.

Pros

Diesel engines have some great advantages, including:

- Durable and reliable powerplant

- No spark plugs required

- Offers better fuel economy

- Well-suited to heavy-duty applications

- Lasts longer than most gasoline engines

- Higher torque ratings

Cons

That said, diesel engines do also have some pitfalls:

- Components cost more to repair/replace

- Diesel can gel at higher temperatures than gasoline freezes

- Harder to start in lower temperatures

- Emissions systems can be particularly costly to repair/replace

- Less common in passenger vehicles than gasoline engines

What Are the Signs a Diesel Engine is Failing?

A trained ear can identify a failing diesel engine before it’s too far gone, but a visual assessment often provides clues as to the source of the potential problem. Reduced performance and fuel efficiency, increased oil consumption or smoke emission, unusual noises, and difficulty starting are the most prominent signs a diesel engine requires immediate attention.

While diesels tend to be more robustly built, they still require quick action to mitigate any further damage caused by failed components.

How To Prolong a Diesel Engine’s Lifespan

Specific maintenance intervals vary between diesel engines, but biannual inspections can help identify and address any concerns before they become significant. Routine oil changes and air filter exchanges keep a diesel engine in proper working order, but there’s more to maintaining a diesel engine than the basic preventive services.

For example, quality diesel fuel and other vital fluids can significantly impact the engine’s lifespan. A clogged filter can wreak havoc on the horsepower and torque most diesels require to get the job done. When not in use, diesel engines also require fuel treatment to maintain the system until it’s time to hit the pavement again.

Besides oil and fuel, diesel engines rely on the cooling system to keep engine temperatures within an acceptable range. Any gasoline or diesel engine won’t last long with extremely hot internal temperatures. Diesel owners must also maintain the complex emissions systems, which can be costly to repair and replace.

Built To Last

Protect the longevity of your diesel vehicle with routine maintenance, proper care, and high-quality products designed to perform in even the most extreme circumstances. Cadence offers a wide range of superior lubricants from the brands you trust.

Call us at 336-629-2061 to speak with a friendly and knowledgeable representative about keeping your diesel engine on the road, no matter the job ahead.

Sources:

Exhaust Gas Recirculation | DieselNet

Diesel fuel explained | U.S. Energy Information Administration (EIA)

Use of diesel | U.S. Energy Information Administration (EIA)